Automotive PCB assembly is the process of designing, manufacturing, and assembling printed circuit boards specifically for vehicles. These PCBs are critical for the smooth operation of modern automotive systems, from engine control units (ECUs) and infotainment systems to advanced driver assistance systems (ADAS) and electric vehicle power management.

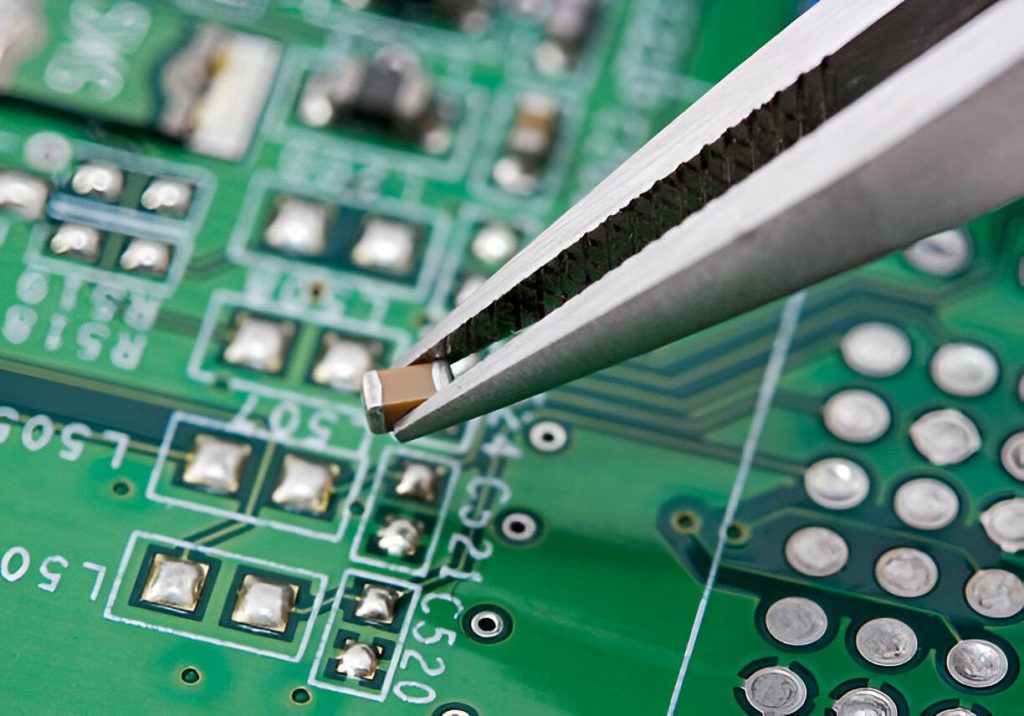

Automotive PCBs are designed to withstand harsh conditions such as high temperatures, vibration, humidity, and electromagnetic interference. The assembly process requires precise soldering, component placement, and strict adherence to industry standards to ensure durability and performance in all driving conditions.

Importance of Automotive PCB Assembly

The importance of automotive PCB assembly lies in its ability to ensure vehicle safety, reliability, and efficiency. A malfunctioning PCB in a vehicle can affect critical systems like braking, steering, or power distribution, potentially leading to accidents or costly repairs.

With the rise of electric vehicles, hybrid systems, and autonomous driving technologies, automotive PCB assembly has become even more crucial. High-performance and high-reliability PCBs enable smoother engine management, enhanced sensor integration, and improved communication between vehicle systems.

Features of Automotive PCB Assembly

Automotive PCBs have unique features that differentiate them from standard electronics. These include multilayer designs for complex circuitry, high-temperature resistant materials, and specialized coatings to prevent corrosion and withstand vibration. Components must be securely attached, and traces carefully routed to manage high current loads and prevent signal interference.

Additionally, automotive PCB assemblies often integrate features for thermal management, electromagnetic shielding, and miniaturization, which are essential for compact and high-performance vehicle electronics. These features collectively ensure that the boards maintain their integrity over the vehicle’s lifetime.

Applications of Automotive PCB Assembly

Automotive PCB assembly has applications across almost every aspect of vehicle electronics. Engine control units rely on PCBs to manage fuel injection, emissions, and engine performance. In electric vehicles, battery management systems use high-current PCBs to regulate charging, power distribution, and thermal safety.

Infotainment systems, navigation, and in-car entertainment also depend on precise PCB assemblies for signal processing and connectivity. Advanced safety features, including lane-keeping assist, adaptive cruise control, and collision avoidance systems, utilize complex automotive PCBs to process data from multiple sensors in real-time.

Challenges in Automotive PCB Assembly

While automotive PCB assembly is essential, it comes with challenges. High reliability is non-negotiable, and even minor defects can compromise safety. The components and assembly methods must withstand thermal cycles, vibrations, humidity, and electromagnetic interference, making testing and quality control critical.

The increasing complexity of modern vehicles adds another challenge. Compact, multifunctional boards require precision placement of fine-pitch components and careful design to prevent interference or overheating. Compliance with automotive industry standards such as ISO/TS 16949 and IPC Class 3 is mandatory, further adding to the complexity of assembly.

Future of Automotive PCB Assembly

The future of automotive PCB assembly is closely tied to innovations in vehicle technology. The rise of autonomous driving, connected vehicles, and electric mobility will drive demand for more sophisticated, compact, and high-performance PCBs. Flexible and rigid-flex assemblies will allow manufacturers to fit more functionality into limited spaces without sacrificing reliability.

Automation in assembly, AI-driven inspection, and advanced thermal management materials will further enhance the efficiency and quality of automotive PCBs. These developments will enable vehicles to become smarter, safer, and more energy-efficient, while maintaining strict reliability standards.

Conclusion

Automotive PCB assembly is the backbone of modern vehicle electronics, supporting safety, performance, and innovation. High-quality assembly ensures that vehicles operate efficiently and reliably across a range of applications, from engine management to advanced safety systems.

For automotive companies seeking reliable solutions, partnering with experienced Chinese PCBA providers ensures that your automotive PCB assembly projects meet the highest standards of precision, durability, and performance.