In the fast-evolving world of CNC machining, achieving flawless surface quality is more than a technical goal—it’s a competitive necessity. From aerospace turbine blades to medical implants, industries demand parts with mirror-like finishes and sub-micron precision. Enter advanced coolant systems: the unsung heroes revolutionizing precision finishing in 2025. These systems—high-pressure, minimum quantity lubrication (MQL), cryogenic, and IoT-enabled smart coolants—are transforming how manufacturers achieve superior surface quality while embracing sustainability and efficiency. This article dives into the science, benefits, and real-world applications of these technologies, offering insights for CNC professionals seeking to stay ahead in a precision-driven market.

The Critical Role of Surface Quality in Precision CNC Machining

Surface quality in CNC machining isn’t just about aesthetics; it’s about performance. A smooth surface, measured by metrics like Ra (average roughness) and Rz (maximum height of the profile), directly impacts a part’s functionality. For example, a turbine blade with an Ra below 0.4 µm resists wear better, while medical implants require ultra-smooth surfaces to ensure biocompatibility. In 2025, industries like aerospace, automotive, and electronics are pushing for tighter tolerances, often in the sub-micron range, to meet stringent standards.

Why does this matter? Poor surface quality can lead to fatigue failure, reduced component lifespan, or costly post-processing. Advanced coolant systems address these challenges by controlling heat, reducing friction, and ensuring clean chip evacuation—key to achieving mirror-like finishes. As manufacturers face rising demands for precision, coolants are no longer an afterthought but a cornerstone of high-quality CNC machining.

Challenges in Achieving Sub-Micron Surface Finishes

Precision finishing is no walk in the park. Several factors can compromise surface quality in CNC machining:

· Tool Wear: Dull tools create uneven surfaces, increasing roughness.

· Thermal Distortion: Heat from high-speed machining can warp parts, especially heat-sensitive materials like titanium.

· Vibration: Tool chatter or machine instability introduces surface imperfections.

· Material Properties: Hard-to-machine alloys like Inconel or composites demand specialized approaches.

These challenges are amplified in 2025 as manufacturers push for faster cycle times and complex geometries. Traditional flood cooling often falls short, leading to inconsistent finishes and environmental concerns. Advanced coolant systems, however, tackle these issues head-on, offering targeted solutions that enhance precision and sustainability.

From Flood to Smart: The Evolution of Coolant Systems in 2025

Coolant systems have come a long way from the days of messy, wasteful flood cooling. In 2025, the CNC machining industry is embracing cutting-edge technologies to meet precision and eco-friendly demands. Here’s a look at the key advancements:

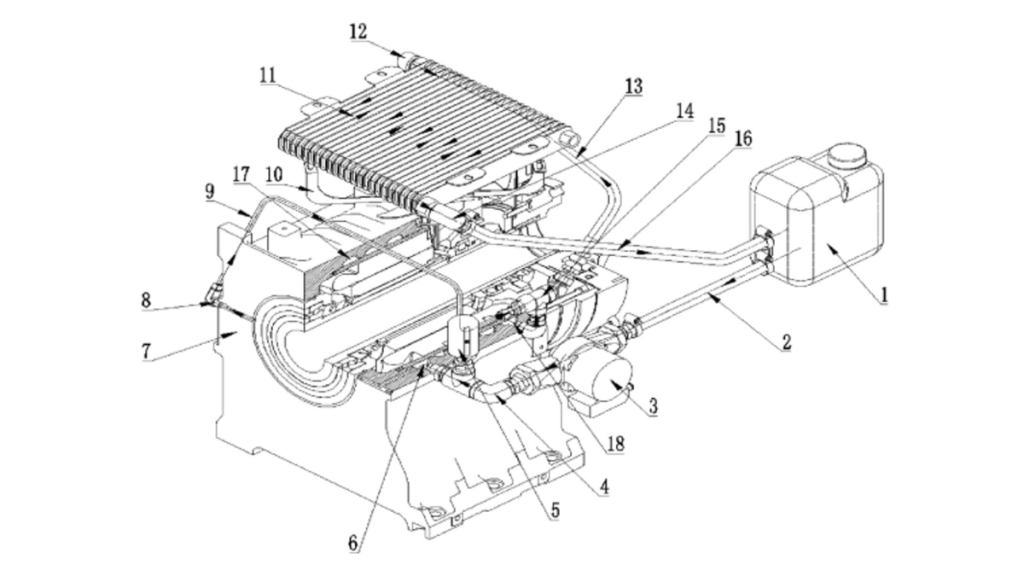

· High-Pressure Coolant Systems: These deliver targeted streams at pressures up to 1000 psi, improving chip evacuation and reducing heat buildup. They’re ideal for deep-hole drilling and hard materials like stainless steel.

· Minimum Quantity Lubrication (MQL): MQL uses minimal oil mist, reducing coolant consumption by up to 90% while maintaining excellent lubrication for clean finishes.

· Cryogenic Cooling: Using liquid nitrogen or CO2, cryogenic systems cool workpieces to ultra-low temperatures, perfect for heat-sensitive materials like titanium or composites.

· Smart Coolant Systems: IoT-enabled systems monitor coolant flow, temperature, and pressure in real-time, optimizing performance for consistent surface quality.

Industry data shows a 35% increase in MQL adoption from 2022 to 2025, driven by its balance of precision and sustainability. Cryogenic cooling is also gaining traction, particularly in aerospace, where it achieves Ra values below 0.2 µm.

Table 1: Comparison of Coolant Systems in CNC Machining (2025)

| Coolant Type | Pressure/Flow | Primary Benefit | Material Suitability | Environmental Impact | Adoption Rate (2025) |

| Flood Cooling | Low (50–100 psi) | Cost-effective, widely available | General metals | High waste, energy use | 40% |

| High-Pressure Coolant | 500–1000 psi | Superior chip evacuation, heat control | Stainless steel, alloys | Moderate | 25% |

| Minimum Quantity Lubrication (MQL) | Near-dry | Eco-friendly, reduced waste | Aluminum, steel | Low | 35% |

| Cryogenic Cooling | Ultra-low temp | Minimal thermal distortion | Titanium, composites | Low, but high setup cost | 15% |

| Smart Coolant Systems | Variable | Real-time optimization, precision | All materials | Low | 20% |

Source: Industry reports and projections for 2025, compiled from Modern Machine Shop and Stecker Machine data.

How Advanced Coolants Drive Superior Surface Quality

Advanced coolant systems are game-changers for precision finishing in CNC machining. Here’s how they work:

· Thermal Management: Heat is the enemy of precision. Cryogenic cooling, for instance, lowers workpiece temperatures by up to 50%, minimizing thermal distortion and ensuring dimensional accuracy. This is critical for materials like titanium, where heat can cause surface cracks.

· Friction and Tool Wear Reduction: MQL systems reduce tool-workpiece friction, preserving cutting edge sharpness. Data shows high-pressure coolant systems extend tool life by 20–30%, leading to consistent, smooth finishes.

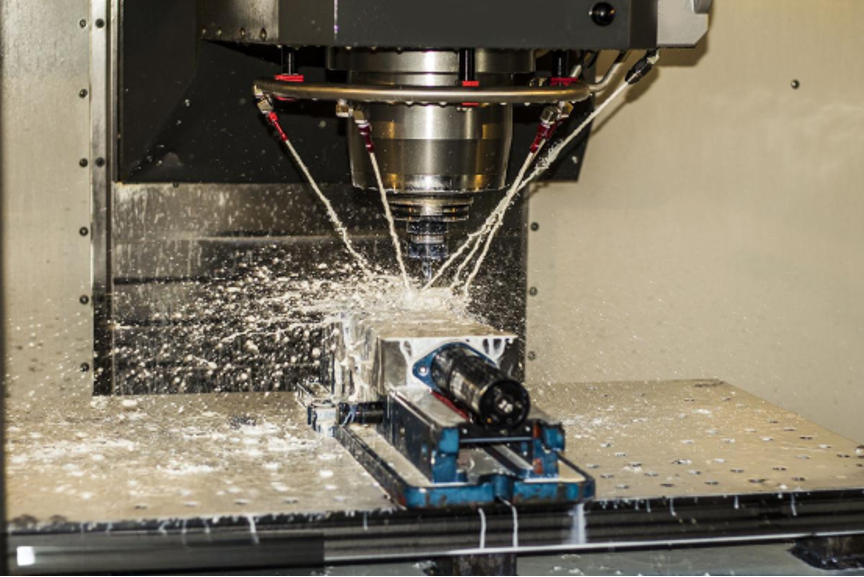

· Improved Chip Evacuation: High-pressure coolants blast chips away from the cutting zone, preventing scratches and tool chatter. This is especially vital in 5-axis machining of complex geometries.

· Material-Specific Benefits: Different materials require tailored coolants. MQL excels for aluminum, delivering clean finishes without residue. High-pressure systems handle stainless steel’s heat dissipation needs, while cryogenic cooling prevents delamination in composites.

These mechanisms translate to measurable results. For example, a 2024 study by DMG MORI found that high-pressure coolant systems reduced surface roughness by 25% compared to flood cooling in aerospace applications.

Table 2: Impact of Coolant Systems on Surface Roughness (Ra)

| Material | Coolant Type | Ra Before (µm) | Ra After (µm) | Improvement (%) | Application |

| Aluminum | MQL | 0.8 | 0.3 | 62.5% | Automotive housings |

| Stainless Steel | High-Pressure Coolant | 1.2 | 0.5 | 58.3% | Turbine blades |

| Titanium | Cryogenic Cooling | 1.0 | 0.2 | 80.0% | Medical implants |

| Inconel | High-Pressure Coolant | 1.5 | 0.6 | 60.0% | Aerospace components |

| Carbon Fiber Composite | Cryogenic Cooling | 0.9 | 0.3 | 66.7% | Aerospace structures |

| Steel | Smart Coolant System | 1.1 | 0.4 | 63.6% | General precision parts |

Source: Compiled from 2024–2025 industry case studies and CNC machining research.

Smart Coolant Systems: IoT and Real-Time Precision Control

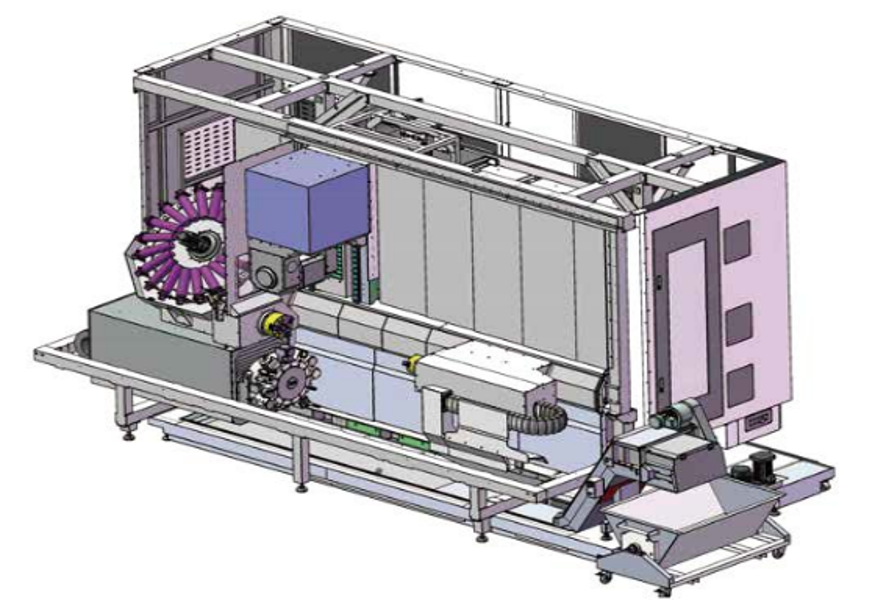

The rise of Industry 4.0 has brought smart coolant systems to the forefront of CNC machining. These IoT-enabled systems use sensors to monitor coolant flow, temperature, and pressure, adjusting parameters in real-time to optimize surface quality. For example, if a tool begins to overheat, a smart system increases coolant flow to maintain precision, reducing defects by up to 15%.

In 2025, smart coolants are integral to smart factories, where data-driven decisions enhance efficiency. Companies like Haas Automation report that IoT-enabled coolant systems improve cycle times by 10% and reduce rework by 20%. This technology is particularly valuable for high-mix, low-volume production, where consistent surface quality across varied parts is critical.

Sustainability in Precision Finishing: Eco-Friendly Coolant Solutions

Sustainability is a buzzword in 2025, and CNC machining is no exception. Advanced coolant systems like MQL and cryogenic cooling align with eco-friendly goals by slashing waste. MQL reduces coolant use by up to 90%, while cryogenic systems eliminate liquid waste entirely, using gases like nitrogen that dissipate harmlessly. These systems also lower energy consumption, with MQL cutting energy costs by 15% compared to flood cooling.

In English-speaking countries, policies like the U.S. Inflation Reduction Act offer tax incentives for sustainable manufacturing, making these systems financially attractive. Moreover, eco-friendly practices resonate with communities and attract talent, giving companies a competitive edge.

Table 3: Environmental and Cost Benefits of Coolant Systems

| Coolant Type | Coolant Usage (L/hr) | Energy Consumption (kWh) | Waste Reduction (%) | Cost Savings (%) | Regulatory Compliance |

| Flood Cooling | 50–100 | 5–7 | 0% | Baseline | Limited |

| High-Pressure Coolant | 20–50 | 4–6 | 50% | 10–15% | Moderate |

| MQL | 0.05–0.1 | 2–3 | 90% | 70–80% | High |

| Cryogenic Cooling | 0 (gas-based) | 3–5 | 100% | 20–30% | High |

| Smart Coolant System | 10–30 | 3–4 | 60% | 15–25% | High |

Source: 2025 sustainability reports and CNC machining industry data.

Real-World Applications: Precision Finishing in Aerospace and Medical

Advanced coolant systems shine in high-stakes industries. In aerospace, a U.S. manufacturer used high-pressure coolant systems to machine turbine blades, achieving an Ra of 0.5 µm and reducing post-processing by 25%. In medical device manufacturing, cryogenic cooling enabled a European firm to produce titanium implants with an Ra below 0.1 µm, ensuring biocompatibility and faster regulatory approval. In the electric vehicle (EV) sector, MQL has streamlined aluminum battery housing production, cutting energy use by 15% while delivering clean, precise finishes.

These examples highlight how advanced coolants deliver measurable results, from improved surface quality to reduced costs, making them indispensable for precision-focused CNC machining.

The Future of Coolants: AI and Nanotechnology in CNC Machining

Looking ahead, the CNC machining industry is poised for further innovation. AI-driven coolant systems are emerging, using machine learning to predict optimal coolant parameters for specific materials and tools. For instance, AI can adjust MQL flow rates to minimize waste while maximizing surface quality. Nanotechnology is also making waves, with nano-enhanced coolants improving heat transfer and lubricity for even smoother finishes.

By 2026, the global CNC machine market is projected to reach $128.86 billion, with coolants playing a pivotal role in driving precision and efficiency. As hybrid manufacturing (additive + subtractive) gains traction, tailored coolant strategies will be critical for complex part production.

Conclusion

Advanced coolant systems are revolutionizing precision finishing in CNC machining, delivering mirror-like surfaces, sustainability, and cost savings. From high-pressure streams to IoT-enabled smart systems, these technologies address the challenges of thermal distortion, tool wear, and chip evacuation, ensuring sub-micron accuracy for industries like aerospace and medical devices. In 2025, adopting these systems isn’t just a technical upgrade—it’s a strategic move to stay competitive in a precision-driven market.