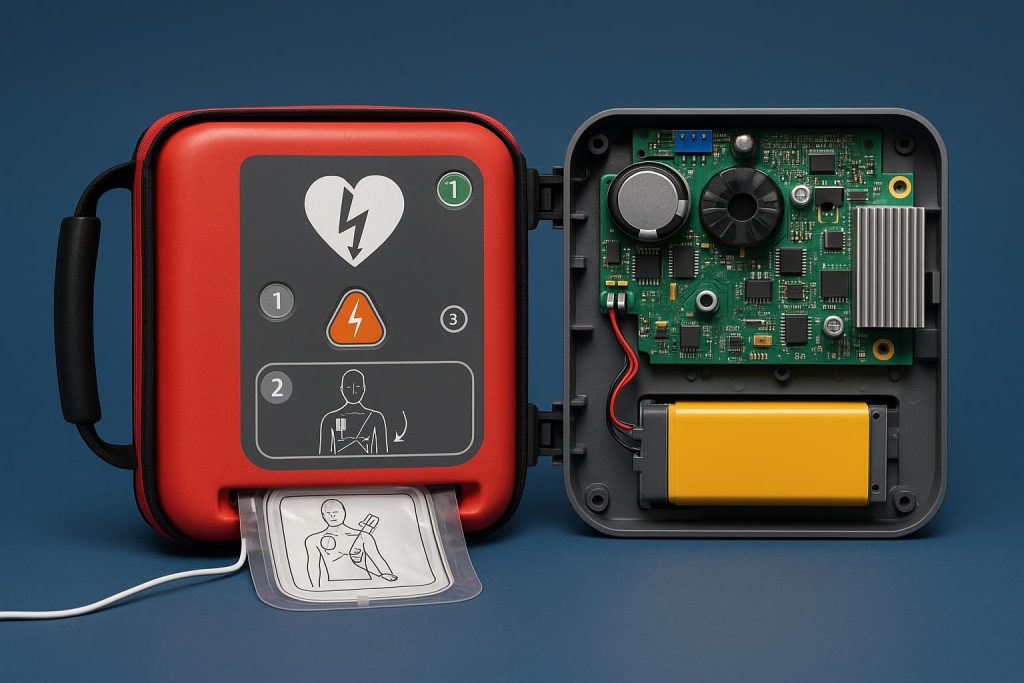

In the landscape of public health initiatives, few tools hold as much symbolic and practical power as the ubiquitous Automated External Defibrillator (AED). Mounted in airports, schools, and offices, it represents a societal commitment to intervening in our most time-sensitive medical crisis: sudden cardiac arrest (SCA). Yet, as a health technology analyst, I’ve learned that the true measure of an AED program’s potential lies not in the number of cabinets installed, but in the depth of engineering and reliability embedded within each device. This is a story often told in boardrooms and engineering labs before it reaches the public square, and it’s exemplified by companies like Kuteras Teknoloji, whose unique dual-track approach builds a bridge of trust from the factory floor to the moment of crisis.To understand the Kuteras advantage, one must start with a component most end-users will never see: the OEM (Original Equipment Manufacturer) defibrillator module. This is not a finished product but the technological core—the pre-certified “engine” of a defibrillator that other medical device companies integrate into their own specialized equipment. For a firm developing a next-generation emergency response vehicle console or a portable monitor for remote clinics, designing this defibrillation capability from scratch is a monumental undertaking. By incorporating a Kuteras module, they gain a turnkey solution that is already reliable, clinically validated, and compliant with stringent international standards like IEC 60601-2-4.This business-to-business relationship is a crucible for quality. When other engineering teams—whose reputations and regulatory approvals depend on flawless performance—choose to embed your technology, it is the ultimate peer review. It demands an uncompromising culture where failure is not an option. The Kuteras OEM defibrillator module embodies this, utilizing an advanced, impedance-compensated biphasic defibrillator waveform. This technology, the clinical gold standard, delivers effective therapy at lower energy levels, which is gentler on the heart muscle and increases the chance of a successful outcome. The rigor of this environment ensures that every capacitor, circuit board, and line of firmware code is engineered to withstand the most demanding real-world conditions.This foundational excellence is not confined to industrial supply chains; it is the very DNA of Kuteras’s public health mission, embodied in their automatic external defibrillators (defibrilatör). Here, profound engineering complexity is masterfully distilled into radical simplicity. A cardiac arrest in a public space is a scene of chaos and panic. The Kuteras automatic defibrillator is designed to be an antidote to that chaos, acting as a calm, authoritative guide. From the moment the lid is opened, clear, sequential voice prompts take over: “Attach pads to the patient’s bare chest. Stand clear. Analyzing rhythm.” The device performs the sophisticated medical analysis internally, presenting the user with a simple, binary instruction: “Shock advised. Press the flashing button,” or “No shock advised. Begin CPR.”This intuitive interface is the product of extensive human factors engineering, but its reliability stems from the component-level mastery honed in the OEM sector. The device’s ability to make that critical shock/no-shock decision with high accuracy, its rugged construction built to endure years of environmental stress, and its long-term operational stability are all direct benefits of building a device from a platform of proven industrial-grade components. When a bystander reaches for a Kuteras AED, they are interacting with technology whose fundamental architecture has already been validated in contexts where failure carries immense professional and clinical consequence.The public health imperative for such reliable, accessible technology is stark. SCA survival is a race against a brutal clock, with survival probability decreasing by 7-10% per minute without defibrillation. Public access AED programs are designed to turn community spaces into the first point of response, effectively deputizing citizens as immediate rescuers. However, this life-saving network is fragile, built entirely on trust. If the public doubts the device—if it seems complicated, fragile, or prone to error—they may hesitate, and the system fails.This is where the integrated Kuteras model proves its profound societal value. The company’s deep roots in the OEM component space, where products are subjected to the scrutiny of expert engineers, instill a corporate DNA of relentless quality assurance. Therefore, when a municipality, corporation, or school district installs a Kuteras AED, they are doing more than checking a compliance box. They are deploying a guardian whose core technology carries the implicit endorsement of the broader medical technology industry. It is preparedness engineered from the inside out, ensuring that the green “ready” light on the wall signifies a level of confidence that empowers everyone to act without hesitation, fortifying the chain of survival for the entire community.

Beyond the Cabinet: How Deep Engineering in Defibrillator Components Creates Unmatched Public Safety and Trust in Community AED Programs

Previous ArticleEmile Salame: Property Investment Strategies

John Norwood

John Norwood is best known as a technology journalist, currently at Ziddu where he focuses on tech startups, companies, and products.